Vertikala plocktruckar PXV upp till 1.200 kg

Den nya dimensionen inom orderplockning

- Lastkapacitet 1200 kg

- Griphöjd 14500 mm

- Hastighet 13 km/h

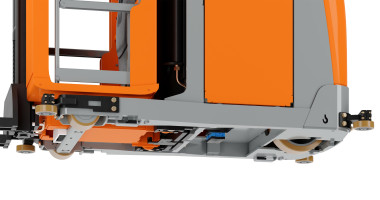

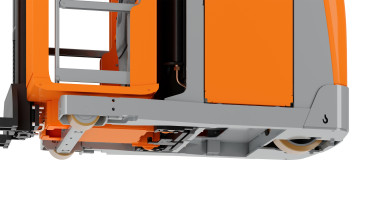

Detta är kungen av orderplockning och imponerar med sin exceptionella godshantering, maximala räckviddshöjd och erbjuder en helt ny nivå av säkerhet och ergonomi. Oavsett om PXV arbetar i lager med smala eller breda gångar, använder ingen annan orderplocktruck plats och tid så smart som PXV vertikal plocktruck. Med en orderplockhöjd på 14,5 meter kan den ”stora” modellen – som har en lastkapacitet på 1200 kg – nå även de högsta hyllorna. Dess lillebror kan samtidigt arbeta på höjder på upp till 7,8 meter med en lastkapacitet på 1000 kg. I båda versionerna garanterar mjuk mastövergång inte bara bekvämt arbete utan också imponerande godshantering. PXV sätter nya standarder även när det gäller användarvänlighet och ergonomi. Föraren stöds av intelligenta assistanssystem, såsom STILL OptiSpeed systemet, som säkerställer högsta möjliga hastighet utan att äventyra körsäkerheten. Den erbjuder också ett utmärkt synfält i last- och körriktningen, plus en rymlig, stötdämpande förarhytt med tippbart skydd för enkel åtkomst till gods. Ytterligare assistanssystem för ännu större säkerhet och effektivitet plus ett flertal utrustningsvarianter kan också väljas individuellt och gör PXV till den perfekta, skräddarsydda följeslagaren för varje lager. Det är den nya dimensionen inom orderplockning.

Utmärkt plats- och lagringseffektivitet:

orderplockhöjd på upp till 14,5 meter

Samtidig lyftning och sänkning

av huvud- och extra lyft

Enkel beröring:

Efingertoppsmanövrering för enkel sänkning av den extra lyften vid orderplockning

Perfekt konfigurerad för att möta alla utmaningar

tack vare det modulära systemet

5 anledningar att välja PXV

Simply easy

Särskilt känslig drift och kontinuerlig kontroll av lyfthastigheten

tack vare proportionalventiler

Intuitiv kontroll

genom ratt eller styrenhet gör det enkelt för föraren att använda alla funktioner, anpassade efter deras behov

Optimal användarkomfort

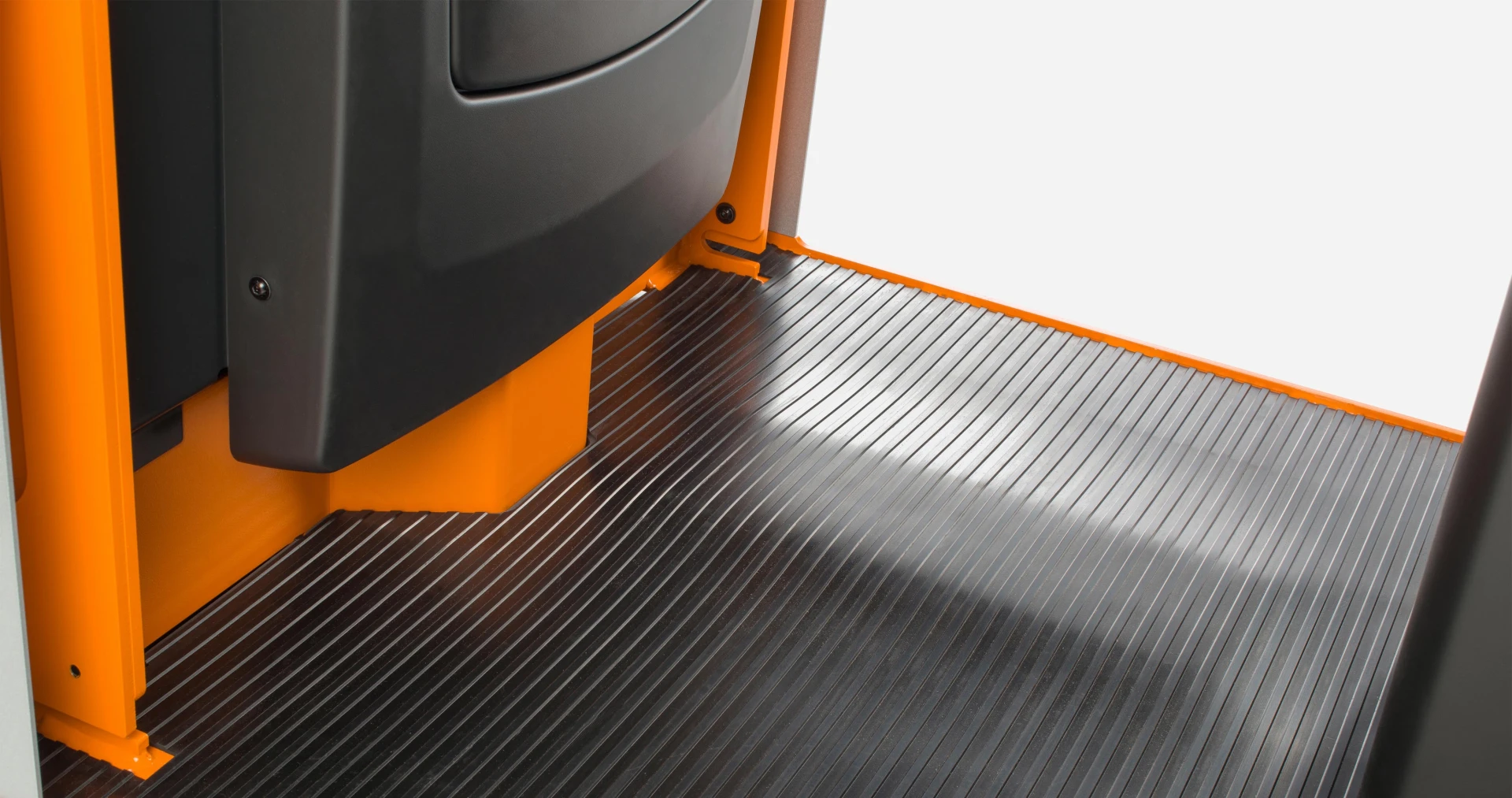

med den rymliga stötskyddade ståplattformen med integrerat död-mans-grepp

Snabb och enkel laddning när som helst

tack vare tillvalsbar lösning för litium-jon-batterie

Simply powerful

Pålitlig tillgänglighet

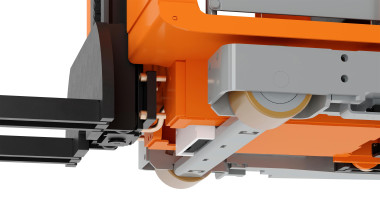

med kraftfull växelströmsdrift med lågt underhåll för både körning och lyft

Effektiv och kraftfull prestanda

för alla kundbehov tack vare individuellt konfigurerbara kör- och lyfthastigheter

Oöverträffat utrymmesnyttjande

med en räckvidd på upp till 14,5 meter

Snabb lyft- och sänkhastighet

tack vare stativ utan frilyft och utan mastövergång

Optimal hanteringsprestanda

tack vare smarta OptiSpeed-assistanssystem med en rad skräddarsydda versioner

Simply safe

Driftsäkerhet garanterad

med den innovativa iGo pilot safety och säkerhetsassistans i gångar

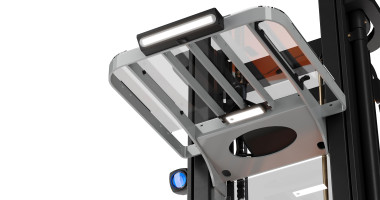

Tillvalsbara tippskydd

tillåter minskat avstånd mellan truck och ställage – för snabb, säker och ergonomisk orderplockning

Säker, bekväm och hälsosam förarhytt

med tillval som knä- och stödkuddar

Optimal truck- och driftsäkerhet

med elektronisk övervakning av batterilåsning

Simply flexible

Individuellt konfigurerbar för ett brett användningsområde

tack vare ett modulärt truckkoncept

Beträdbar pall

låter föraren gå ut på pallen för att plocka skrymmande och tungt gods

Flexibel förarhyttdesign

för enkel integrering av verktyg (tillval)

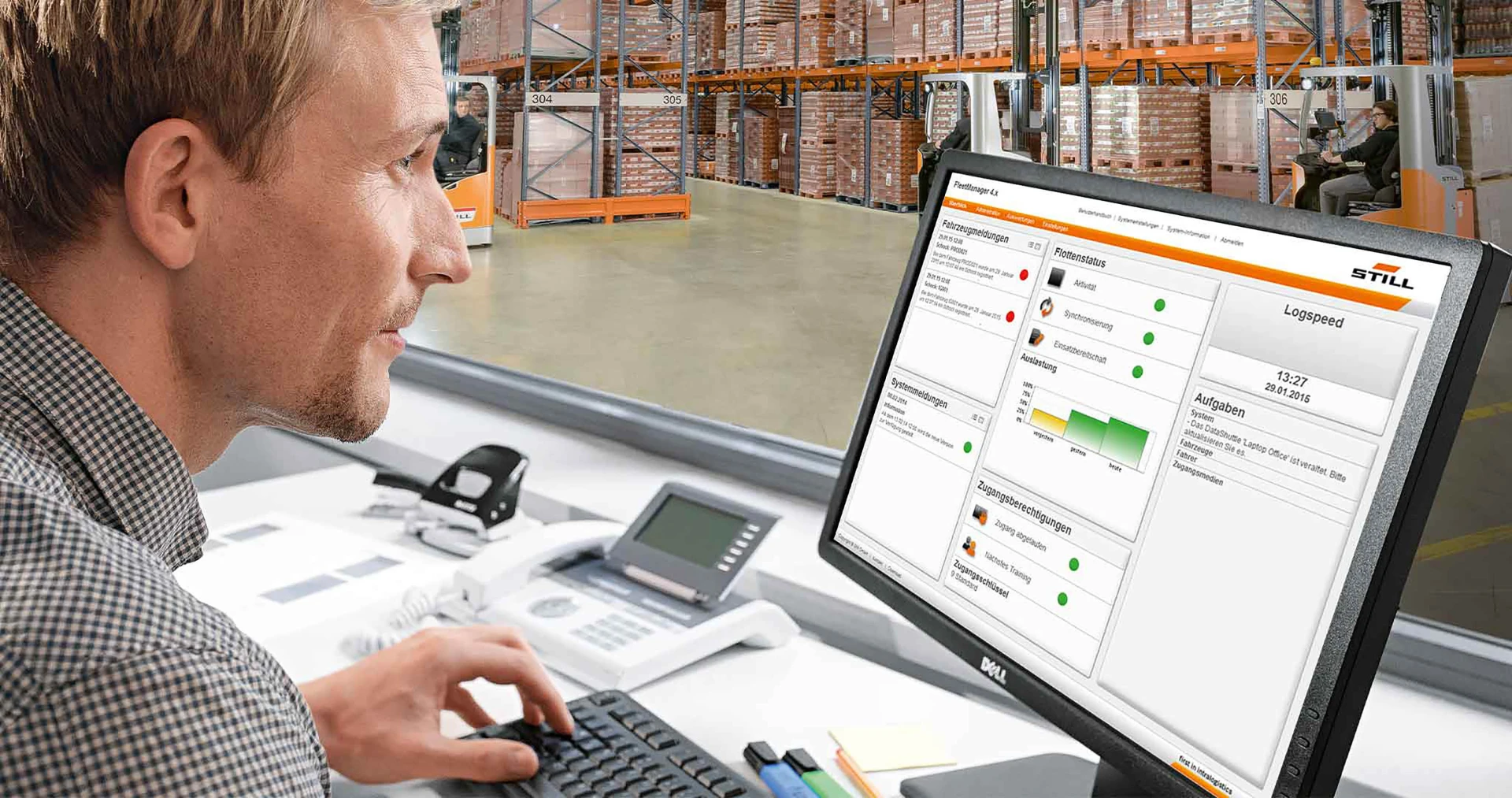

Simply connected

Maximal hantering

med intelligent STILL iGo pilot navigeringssystem och automatisk stoppfunktion

Enkel anslutning till lagerhanteringssystem

för optimal kontroll av varuflödet med STILL iGo pilot gränssnitt

Optimal trucksäkerhet, åtkomstskydd och skademinimering

med STILL FleetManager 4.x

Litiumjonteknik inuti

Det perfekt harmoniserade kraftsystemet för att minska driftkostnaderna och öka trucktillgängligheten.

Mer om STILL Li-Ion-teknik|

Modell

|

Maximal lyftkapacitet (kg)

|

Maximal griphöjd (mm)

|

Körhastighet (km/h)

|

Batterispänning (V)

|

|---|---|---|---|---|

| PXV/Li-Ion | 1200 | 14500 | 13 | 48 |

Filer att ladda ner

Dokumentet för nedladdning är den uppdaterade versionen av manualen för standadtrucken. Den inkluderar inte beskrivningar av kundanpassningar (kundalternativ). Kontakta STILL's revservdelsavdelning när det gäller en specifikt truck. Uppge truckens serienummer och tillverkningsår.